|

Home Intro Technical History Crew Models Gallery Kriegsmarine Archives

More Forum  UPDATES UPDATES |

PROPULSION PLANT

From a tactical point of view, the speed of a warship has today lost the importance that it once had. Due to the range and accuracy of modern weapons, the use of tactical manoeuvres, based on speed, are in most cases useless. But in the days of the big guns and heavy armour speed was vital because it allowed the faster ship to choose under what circumstances a battle was to be fought. Speed is the result of the struggle between the power of the propulsion plant and the resistance that the water offers to the advance of the ship. Therefore, speed will depend on the propulsion system utilized and the hydrodynamic capabilities of the hull.

The battleship Bismarck had a steam propulsion plant that amounted to only 9% of the ship's weight. Within the ship’s boilers, fuel oil was burned and feed water heated, thus producing steam. This steam reached very high pressure and was then delivered to the turbines that turned the propellers.

Boilers.

On Bismarck, the steam power was produced by twelve Wagner Hochdruck high pressure steam-heated boilers distributed in six watertight compartments (boiler rooms) that were located amidships in sections XI and XIII.

Boiler Room Arrangement and Numeration.

· Port No. 1 Boiler Room, with boilers No. 1529 and No. 1532. Section XI.

· Port No. 2 Boiler Room, with boilers No. 1535 and No. 1538. Section XIII .

· Centre No. 1 Boiler Room, with boilers No. 1530 and No. 1533. Section XI.

· Centre No. 2 Boiler Room, with boilers No. 1536 and No. 1539. Section XIII.

· Starboard No. 1 Boiler Room, with boilers No. 1531 and No. 1534. Section XI.

· Starboard No. 2 Boiler Room, with boilers No. 1537 and No. 1540. Section XIII.

Individual Boiler Arrangement and Numeration.

· Boiler No. 1529 in port No. 1 Boiler Room.

· Boiler No. 1530 in centre No. 1 Boiler Room.

· Boiler No. 1531 in starboard No. 1 Boiler Room.

· Boiler No. 1532 in port No. 1 Boiler Room.

· Boiler No. 1533 in centre No. 1 Boiler Room.

· Boiler No. 1534 in starboard No. 1 Boiler Room.

· Boiler No. 1535 in port No. 2 Boiler Room.

· Boiler No. 1536 in centre No. 2 Boiler Room.

· Boiler No. 1537 in starboard No. 2 Boiler Room.

· Boiler No. 1538 in port No. 2 Boiler Room.

· Boiler No. 1539 in centre No. 2 Boiler Room.

· Boiler No. 1540 in starboard No. 2 Boiler Room.

Boiler Data.

Evaporation heating surface: 380 m².

Superheater heating surface. 120 m².

Air pre-heat surface: 685 m².

Feedwater pre-heating temperature: 160º C.

Saturated steam temperature: 287º C.

Superheated steam temperature: 450º C.

Operating steam pressure: 55-56 atmospheres (58 Kg/cm²).1)

Intervention pressure, safety valves: 58 atmospheres (63 max.).

Authorised pressure: 64 atmospheres.

Steam production: 132 kg per m² of surface.

Capacity: 144 m³.

Weight of boiler with water: 52.8 tons.

Weight of (warm) water content: 4.85 tons.

Turbines

There were three Blohm & Voss turbine sets in separate compartments (turbine rooms) located in sections VIII and X. The centre turbine room located in Section VIII, and the portside and starboard turbine rooms in Section X. The German Navy preferred the three-shaft drive for its capital ships, unlike most foreign nations that used four-shaft drives. This saved weight and permitted a better distribution within the hull. Each set of turbines served one propeller shaft and had different sections:

· The HP reaction turbine: a Curtis wheel with 40 stages.

· The IP turbine: a double-flow 15-stage reaction turbine.

· The LP turbine: a 9-stage reaction turbine supporting the condenser slung below it.

· The HP astern turbine was a single Curtis wheel.

· The LP astern turbine was of the divided double flow type.

· No cruising turbine was fitted on Bismarck.

The high and intermediate pressure turbines made 2,800 R.P.M. at full power, and the low pressure turbine made 2,400 R.P.M.

| Turbine section | Turbine revolutions (rpm) | Shaft revolutions (rpm) |

| High pressure (HP) turbine | 2,880 | 270 |

| Intermediate pressure (IP) turbine | 2,880 | 270 |

| Low pressure (LP) turbine | 2,430 | 190 |

| High pressure astern turbine | 2,025 | 180 |

| Low pressure astern turbine | 1,715 | 190 |

| Cruising turbine (only on Tirpitz) | 4,220 | 170 |

The plant generated a total horse power of 150,170 hp and provided the battleship with a maximum speed of 30.1 knots. The ship also benefited from the low prismatic coefficient of its hull that was 0.56.

The fuel capacity was 8,294 mt and the range 8,525 nautical miles at 19 knots. Very good when compared to other battleships, and this demonstrates that the ship was intended as an ocean rider.

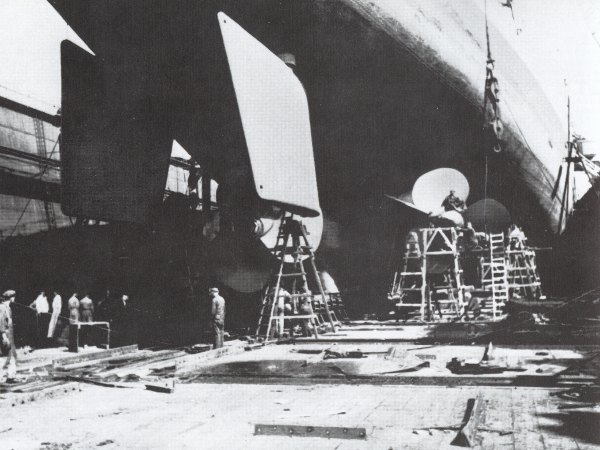

Propellers.

The three propellers were of 4.70 meters in diameter and had three blades. The port and middle propellers rotated counter clockwise and the starboard propeller clockwise. Each propeller had a volume of 2.4 m³ and achieved 270 revolutions per minute at full speed.

Rudders.

The electric steering system controlled two parallel rudders of 24.21 m² each, inclined from the vertical with 8º divergence towards the centreline. Each rudder had a volume of 11.63 m³ including its hanging attachment.

Electrical Power Plant.

The electric plant provided power to all the ship's services such as weaponry, steering, lighting, cranes, fans, gyros etc. It had a total output of 7,910 kw at 220 volts, with eight 500 kw Diesel generators, five 690 kw turbo-generators, and one 460 kw turbo-generator. These generators were distributed into four compartments (plants). The starboard electric plant No. 1 and the port electric plant No. 2 (E-Werk 1 und E-Werk 2) were located in section VIII, and had four 500 kw diesel generators each. The starboard electric plant No. 3 and the port electric plant No. 4 (E-Werk 3 und E-Werk 4) were located in section XIV, and included five 690 kw turbo-generators, and one 460 kw turbo-generator.

In addition, in section VII adjacent to the electric plant No. 1 on the starboard side, was the Diesel motor room No. 1 (WE-E-Werk 1). This room included a Type MWM RS 38 S Diesel engine developed by Motorenwerke Mannheim A.G. serial number 170093 (170094 in Tirpitz). It was a 6-cylinder engine that gave a normal output of 460 ehp at a speed of 600 r.p.m.; however, a 20% overload to 550 ehp was possible for 30 minutes if necessary. The 550 kVA AC Diesel generator of the type P23 FA925 10 Spez. B2 (P23 FA925/10+RP 91 sp. in Tirpitz) was manufactured by Garbe-Lahmeyer and numbered 377071 (376848 in Tirpitz). It generated alternating current.

| Generators | Output | |

| Starboard Electric Plant No. 1 | 4 x 500 kw diesel generators | 2,000 kw |

| Port Electric Plant No. 2 | 4 x 500 kw diesel generators | 2,000 kw |

| Electric Plants No. 3 and No. 4 | 5 x 690 kw turbo generators 1 x 460 kw turbo generator |

3,450 kw |

| 7,910 kw |

| Boilers: | of high-pressure (58 Kg/cm²) and high temperature (450º C) in six compartments |

| Turbines: | in three compartments |

| Horse power: | |

| Propellers: | of 4.70 meters in diameter each |

| Rudders: | with 8º divergence towards the centreline |

| Diesel generators: | One of 550 kVA AC |

| Turbo generators: | One of 460 kilowatts DC |

| Total electric output: | |

| Range: | 8,900 nautical miles at 17 knots 8,525 nautical miles at 19 knots 6,640 nautical miles at 24 knots 4,500 nautical miles at 28 knots |

| Fuel: |

1) To calculate from atmospheres to kg/cm² multiply by 1.0332.

To calculate from atmospheres to PSI multiply by 14.696.

To calculate from kg/cm² to atmospheres multiply by 0.9678.

To calculate from kg/cm² to PSI multiply by 14.224.

2) Data from Brown Boveri turbines installed on the battleship Tirpitz.

| Home Guestbook Quiz Glossary Help us Weights & Measures Video Credits Links Contact |